Compared to the sky-high prices of Burmese rubies and the limited production from other sources, Mozambique rubies offer comparable beauty with abundant supply, making rubies more accessible to the average consumer.

I have previously written a detailed article about Mozambique rubies titled “In Just 10 Years, She Rose to the Top of the Gemstone World as a ‘New Noble’!” which readers can revisit. Today, I want to take you on a journey following in the footsteps of GIA gemstone experts from 10 years ago, to see how the rubies we buy are mined!

Origins

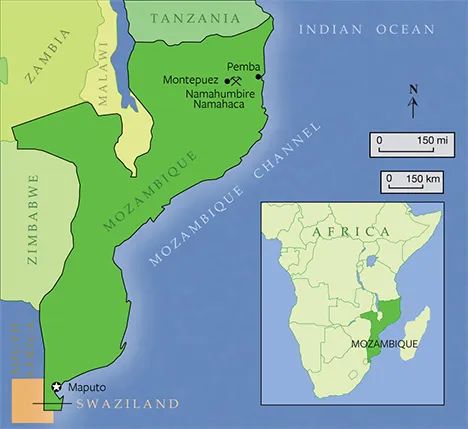

Mozambique is situated in southeastern Africa along the Indian Ocean. The Mozambique Channel separates it from Madagascar, another gem-producing country. To the north, it borders Tanzania, a significant source of tanzanite. South Africa lies to the south, while Zimbabwe, Malawi, and Zambia border it to the west.

Mozambique is rich in natural resources, including natural gas, coal, titanium, and hydroelectric power. Agriculture is also crucial to its economy, with crops such as cotton, cashews, sugarcane, tea, cassava, fruits, potatoes, and livestock including beef and poultry. In the late 2000s, the ruby mining industry emerged as a new economic component after significant developments in the northeastern part of the country.

The Montepuez ruby deposit was discovered in May 2009. Shortly after, thousands of miners began illegal operations in the area with foreign support. In June 2011, Mozambique’s Mwiriti Ltd. partnered with British multinational colored gemstone supplier Gemfields to form the Montepuez Ruby Mining company (MRM). MRM obtained a 25-year concession in March 2012 and invested heavily in improving the deposit’s infrastructure, machinery, staffing, safety, and public relations.

Although many people are unaware that Mozambique is a ruby source, the deposits near Montepuez are considered by industry insiders to be the world’s largest ruby supply. Gemfields’ first Mozambican ruby auction in June 2014 in Singapore marked a milestone in global trade. The auction generated $33.5 million, putting the MRM ruby deposit in the spotlight, as the entire inventory came directly from ongoing bulk sampling at Montepuez, which would guide further development of large-scale mining operations.

MRM employs about 400 staff at the mine, with an additional 300 contractors. Besides bringing in experienced personnel from other countries, the company has trained local Mozambicans, who make up the vast majority of the workforce, to achieve high skill levels.

In September 2014, GIA researchers Tao Hsu, Vincent Pardieu, and Andrew Lucas visited the Montepuez ruby deposit. The trip, hosted by MRM, aimed to witness the evolution and operations of this major deposit and collect research samples for GIA laboratories.

Geological Situation

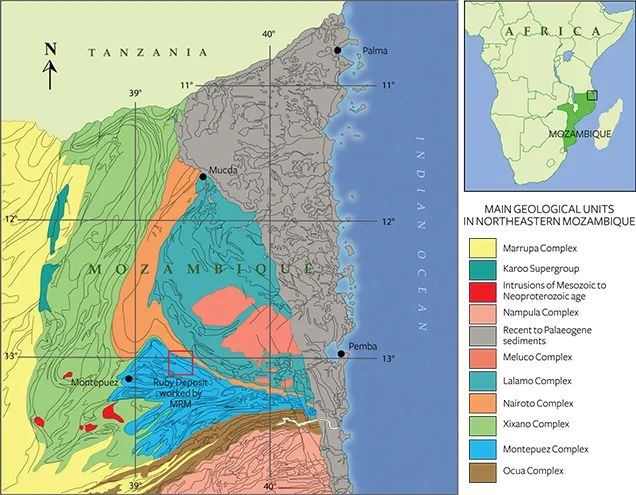

Northeastern Mozambique is situated at a geological junction between the north-south trending Mozambique Belt and the east-west trending Zambezi Belt. Both are Neoproterozoic (about 500-800 million years old) orogenic belts within the global Pan-African tectonic framework. Several major geological complexes are separated by major thrust and shear zones. Complex thermal and deformation events provided ideal temperatures and pressures for the formation of economically important minerals such as rubies and garnets.

The Montepuez ruby mine is located about 150 kilometers west of the beautiful coastal city of Pemba. Its mineral composition indicates that the deposit underwent a series of complex metamorphic processes, with metamorphic pressures of 0.4-1.1 GPa and temperatures of 550-750°C.

Rubies can only form under very limited pressure and temperature conditions, and only in the presence of sufficient aluminum, chromium, and oxygen. The MRM exploration area is located on one side of an east-west trending near-vertical axial plane fold. At least four distinct deformation phases occurred in the area, with intense deformation complicating rock units at various scales, making exploration and prediction of the primary deposit extremely complex.

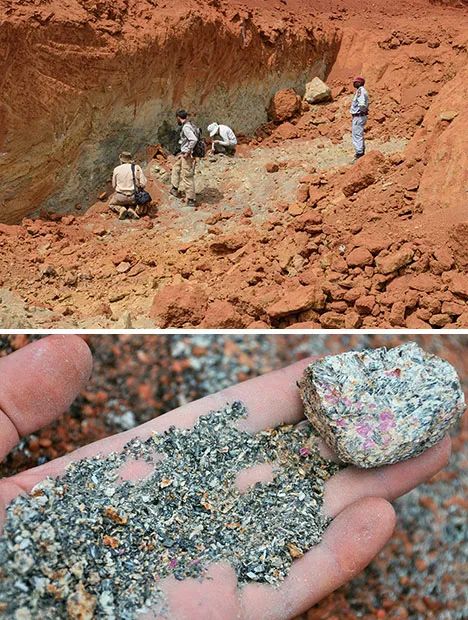

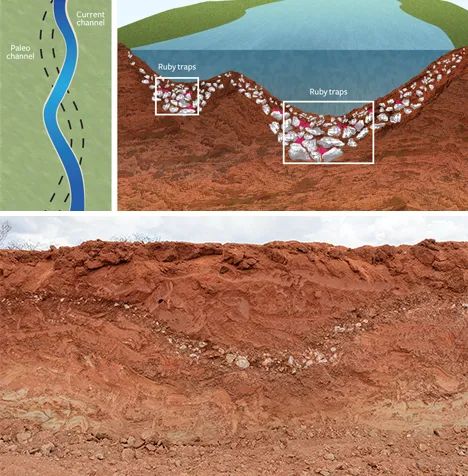

Maninge Nice is the only primary deposit discovered so far, with pit walls showing a clear contact zone between topsoil and weathered ruby-bearing amphibolite, which is very fragile and easily breakable by hand (shown in the image above).

“Runaway” Rubies

After hundreds of millions of years of erosion, Montepuez’s secondary ruby deposits are easier to discover and mine than the primary deposits. Rubies that “escaped” from their host rocks were screened, carried away, and deposited by passing water flows due to their “heavy and hard” nature (upper right image).

The morphology of the channels carrying these rubies (upper left image) changed over time, with the channels “moving” constantly over hundreds of millions of years, leaving traces of their original flow that geologists call “palaeochannels.”

The drainage system in the mining area is well-developed. The local topography generally causes water to flow from north to south, with current channels easily recognizable and manageable. MRM targets these palaeochannels because they contain large quantities of high-quality rubies.

Pit 3 is located along a major palaeochannel and is the largest one currently being mined by MRM. The pit walls show excellent cross-sections of former channels (lower half of the image). The size of the gravel increases noticeably from the edges to the bottom of these “pits,” with gravity causing heavier gravel to settle and concentrate at the bottom of the depressions. Larger debris slows water flow, and due to the relatively high specific gravity of rubies, they settle along the bottom of the depressions along with other heavier minerals.

“Dig, Dig, Dig”

MRM’s concession area covers approximately 400 square kilometers, including both primary and secondary deposits. Most sampling is conducted in secondary deposits, but plans are in place to sample both types within the current fiscal year. The only area with both primary and secondary gravels is Maninge Nice (shown in the image above), named for producing “nice” gemstones.

Another major sampling area is Mugloto. Pit 3 is located in an area of Mugloto called Mashamba (shown in the image below). Pit 5 is in an area called Mercado, which means “market” in Portuguese, as it was once a market for illegal miners.

Secondary deposits contain large amounts of fine gravel, which is relatively easy to sample. In secondary deposits, gem-bearing gravel is covered by overburden. MRM typically uses two excavators to sample gravel down to bedrock, with one removing the overburden to expose the gravel and the other loading the gravel into trucks for transport to the processing plant (shown in the image below).

The long-term sampling strategy for secondary pits depends primarily on geological conditions. MRM has opened several large-scale sampling points based on exploration spiral drills and 50×50 meter small pits, all along a single palaeochannel. In one area, the company plans to merge several pits when appropriate to form a large-scale operation along the palaeochannel.

The palaeochannel in this area is about 4.5 kilometers long, with pit widths ranging from 50 to 150 meters. The large pit connecting them is about 2.5 kilometers long and expected to grow longer. Eventually, this will form a massive colored gemstone pit mining operation area.

According to MRM’s conservative estimates, 1.7 million tons of potentially gem-bearing gravel will be removed from pits along this palaeochannel. This will involve processing 15 million tons of rock. At the time of the GIA experts’ visit, MRM was using four excavators, with two more on the way. This allows for sampling of more pits, increasing the number of excavators in pits determined to be critical, and digging new pits.

Digging Deeper

The bulk sampling and resource analysis phase was planned to be completed by 2016 to gain a clearer understanding of the mine’s potential output and lifespan. Primary and secondary deposits require different drilling methods and strategies. Exploring secondary deposits aims to better determine the distribution of ruby-bearing gravel layers in the mining area. The gravel layer contours and ruby concentration data will be constructed from this information.

Auger drilling, a method not typically used by GIA researchers, is employed to explore secondary deposits. An auger drill consists of a rotating spiral screw inserted into the ground. The shape of the spiral blades brings soil up from the borehole.

As soil is removed from the hole, workers clear loose gravel from between the drill bit blades (shown in the image above). This differs from core drilling, which extracts solid or fragmented cores from hard rock. Auger drilling is considered an effective method for exploring soft or weakly weathered rock.

Gemfields’ geologists divide the target area into several blocks and drill holes on a 100-meter grid. The drill bit and other equipment are transported to the drilling site by truck. Each exploration team consists of a geologist, a technician, and four to five workers.

It takes about an hour to drill a hole, from setting up the machine to refilling the borehole. The goal is to complete 8 to 9 holes per day. Samples are taken at different depths as drilling progresses (shown in the image below).

Drilling results indicate the depth and thickness of ruby-bearing gravel layers at each location. After completing thousands of drills, contour maps are drawn showing the depth and thickness of gravel layers in the area. Before the GIA experts’ visit, auger drilling had already delineated the aforementioned 2.5-kilometer palaeochannel and many other potentially rich mining points.

Topsoil sampling also gives geologists a good understanding of how much waste needs to be removed before reaching the mineral-bearing gravel layer.

To obtain representative samples, soil removed from the drill bit above the ruby-bearing gravel layer is thoroughly mixed for every meter drilled, and 50-100 gram samples are taken for chemical analysis to quantify certain elements. The analysis results guide further exploration and evaluation.

In the gravel layer, 10-20 kilograms of ruby-bearing gravel is drilled, bagged, and transported to the washing and sorting plant for processing to roughly estimate ruby concentration (shown in the image below). The top one to two meters of bedrock are also washed to minimize the risk of losing rubies. All remaining samples are carefully preserved for future reference. The process is completed by refilling the boreholes in an environmentally friendly manner.

Ultimately, this is a technical job, and understanding the geological conditions of primary deposits is key to maintaining mine profitability. Through extensive core drilling, geologists have made some important underground discoveries.

Ruby-bearing amphibolite is typically found at depths of 10-30 meters (shown in the image below). Exploration teams also drill into the basement rock layers to see if amphibolite reappears. Sometimes they discover secondary ruby-bearing gravel layers above primary deposits.

How Many Rubies Are Actually Mined?

As part of its bulk sampling operations, MRM processed approximately 1.8 million tons of rock at the Montepuez mine, recovering about 8 million carats of rubies and sapphires of various colors. The company hoped to double its production capacity to 3.6 million tons of rock in 2015 and eventually increase this figure to 10 million tons of rock per year.

The actual recovery rate of rubies in secondary deposits is difficult to predict. The quantity of rubies per ton varies greatly, as does the quality of recovered rubies. For example, Mugloto Pit 3 has a relatively low recovery rate of 0.60-1 gram per ton of ore. However, even with a low recovery rate, it is profitable due to the high quality of rubies produced.

This pit also produces some large rough stones weighing 6-8 grams. In contrast, Maninge Nice has a higher recovery rate of 20-35 grams per ton but typically produces rubies of much lower value.

Overall, the recovery rate for primary deposits is approximately 162 carats per ton, while secondary deposits yield about 31 carats per ton.

The Beauty Contest Begins

The Montepuez processing plant (shown in the image above) is divided into four main areas: dry screening, waste particle removal, wet screening, and gluing and concentration. The washing process uses two screening systems and two jig systems to separate materials by size (shown in the image below). Both systems employ double-layer screening, with a second screening following the first layer. The washing plant delivers 150 tons of concentrate per hour, containing various rough corundum.

Suction hoses draw gravel from the jigs into tanks. The gravel is then poured into bags and sent to sorting stations. Concentrated gem gravel is loaded into the back of sorting boxes, which are rectangular boxes with slanted glass windows for easy viewing. Subsequently, rubies are separated from gravel and garnets.

To reduce the possibility of theft, sorters never actually touch the rubies throughout the process. They wear sleeves with rubber gloves (shown in the image below) and identify stones based on visual appearance, particularly crystal morphology. They then throw the extracted stones into two holes, one for garnets and another for corundum (rubies and sapphires).

Next, a senior staff member and a security team member open the boxes containing the gemstones, and the corundum is washed and sorted. The rough stones are divided into dark and light tones, representing rubies and pink sapphires, respectively. Rubies are further categorized into four classes: premium, facet-grade, translucent-opaque, and basic corundum.

The grading of premium ruby rough is conducted in an adjacent room, first by color and then by clarity. White tables provide a background, while windows in front of the grading machines offer ample daylight for color grading. The Gemfields ruby grading system is based on the rough stone’s size, color, shape, and clarity (shown in the image below).

Knowledge is Power

Montepuez rubies are crucial to the trade due to their high production volume and wide range of weights and sizes. The color of these rubies fills a gap between the two traditional ruby sources: Myanmar (high fluorescence, low iron content) and Thailand/Cambodia (weak fluorescence, high iron content).

The red color in rubies is attributed to chromium, but the presence of iron alters the ruby’s color, reducing the fluorescence caused by chromium. Montepuez rubies have a highly versatile iron content, ranging from almost as low as Myanmar rubies to as high as those from the Thai-Cambodian border. This means their diverse colors can satisfy different market demands.

Among the harvested rubies, a small portion possesses excellent color and clarity without requiring heat treatment, while others have less desirable clarity due to fractures or inclusions. Heat treatment can alter the visual appearance of these lower-quality rubies. Lead-glass filling is used for rubies with numerous fractures, while more traditional heat treatment (with or without borax-based additives) is applied to rubies with fewer fractures. Generally, treated rubies are more readily available than untreated ones.

Rubies from each sampling area in Montepuez have slightly different appearances. Those from Maninge Nice appear purplish-red to red. Rough stones from other areas tend to be darker, brownish or orangey, and typically have higher iron content than samples from Maninge Nice – similar to rubies from Thailand/Cambodia.

Rough rubies from the primary deposit at Maninge Nice have sharp edges and angles, with brighter colors due to lower iron content compared to other deposits in the area (shown in the image on the left). Typical secondary deposit rubies from the Mugloto area are mostly rounded due to millions of years of weathering and river erosion, with darker colors resulting from higher iron content.

Although some exceptionally large gems exceed 100 carats, most unheated faceted rubies from Montepuez weigh less than 3 carats. Unheated Montepuez rubies have uniform color, high transparency, and good luster, making them ideal for calibrated cuts.

Experts Also “Pick” Gemstones

Since 2008, the GIA Bangkok laboratory has been collecting reference samples and extracting data from them. The laboratory completed a gemological characteristics study of 131 ruby samples from Mozambique. The team’s primary task is to collect and study ruby, sapphire, and emerald reference samples according to GIA protocols.

At Maninge Nice, the group was allowed to “sweep” for samples under company security supervision (shown in the image above). Due to the high weathering of the amphibolite host rock for rubies, the team collected a considerable number of high-quality samples using rock hammers. These samples met the requirements for laboratory preparation and analysis.

These collected specimens are particularly valuable as they are “Type A” samples. This means that gemologists personally obtained these gems directly from the rock. These valuable reference samples will become an important addition to GIA’s reference sample database.

Unveiling the Source: Where Most of Your Rubies Come From!

Tweet